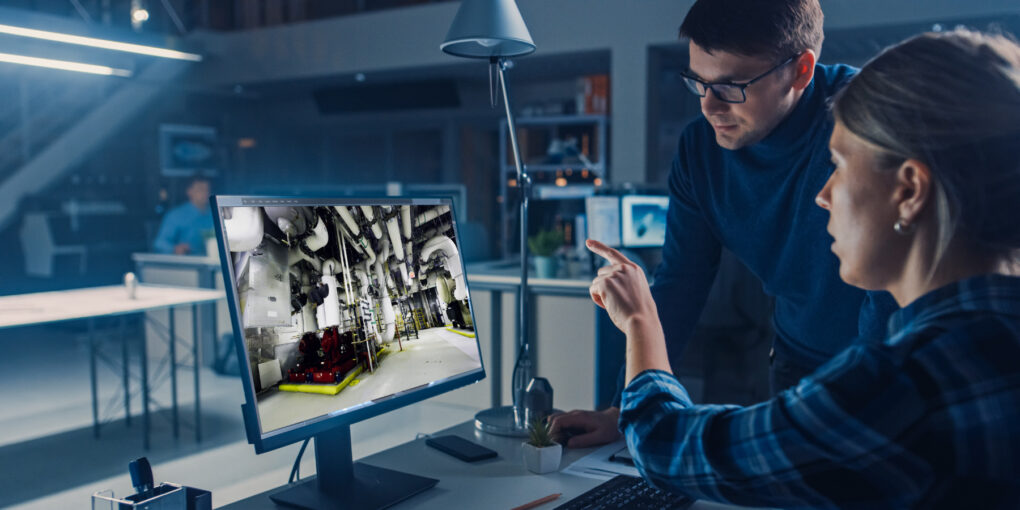

Bring Visual Context to Your Assets.

A visual twin platform connecting engineering and operations through reality capture-based environments.

Who RealityTwin™ is For

EPCs & Reality Capture Providers

Quickly create and maintain accurate digital twins using your 3D scans.

- Merge TLS, SLAM, drone or photogrammetry into one integrated model

- Update only the changed areas—no rescan required

- Prep and clean up scans for retrofits, shutdowns, or upgrades

- Visual collaboration with clients made easy

Ops & Maintenance Teams

Give every team member a visually accurate view of your facilities.

- Seamless integration with ERP, MES, CMMS, IIoT

- Access and manage assets remotely via interactive 3D views

- Cut inspection times and increase on-site safety

- Keep every site aligned with one visual source of truth

RealityTwin™ benefits at a glance

Less time spent in the field

Access and validate site conditions remotely through persistent, updated digital twins.

Reduction in on-site inspection hours

Cut unnecessary site visits by maintaining a trusted visual reference of real-world conditions.

Ready & Connected

Integrates with SAP, Siemens, IBM Maximo, AVEVA, and AWS for data-driven decisions across maintenance and operations.